Insect Nets Reduce Pesticides & Improve Food Safety

Agriplast Insect Nets and Optinets act as a critical physical barrier against pests, allowing farmers to reduce toxic pesticide usage by up to 90% while ensuring the residue-free produce required for premium export markets.

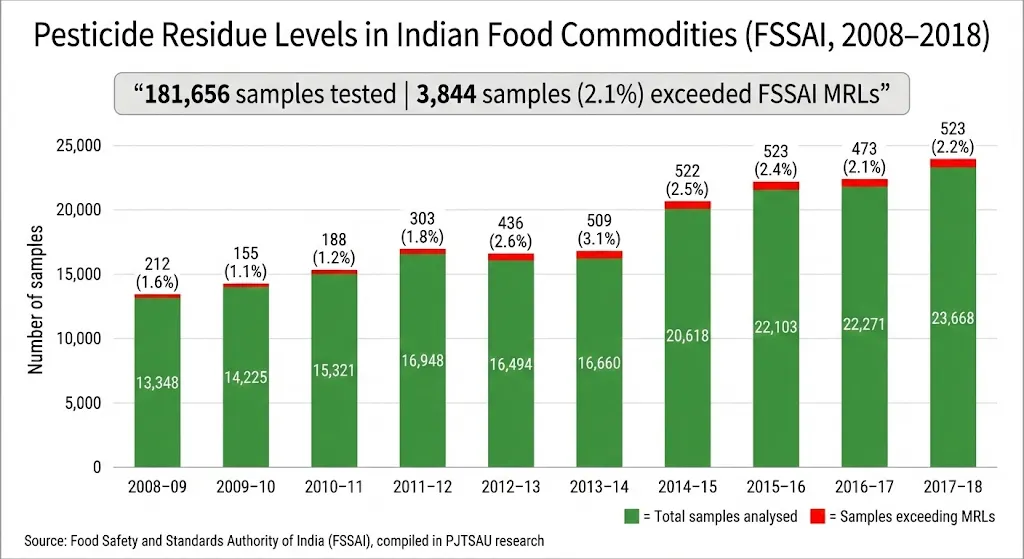

For modern farmers in India, the reliance on chemical pest control has created two critical crises that threaten the sustainability of agriculture:

1. The Threat to Health and Safety Excessive spraying is no longer just an operational cost; it is a public health liability. The sole focus on preventing pest attacks has led to dangerous chemical exposure for farm laborers and high residue levels that compromise the long-term health of consumers. This chemical dependency also contaminates irrigation sources and degrades the ecosystem, making current farming practices increasingly unsustainable.

2. The Barrier to Global Markets Simultaneously, Indian farmers are facing a "market blockade." Strict food safety protocols and Maximum Residue Limit (MRL) violations are now the leading reasons Indian fruits and vegetables are rejected by international exporters and premium supermarket chains. Without meeting these rigorous global standards, farmers are locked out of the most lucrative markets.

The Smarter Solution: Exclusion, Not Chemicals Agricultural insect nets solve both problems by preventing pests like thrips, aphids, and whiteflies from reaching the crop in the first place. By integrating Agriplast’s UV-stabilized nets with Good Agricultural Practices (GAP) and Integrated Pest Management (IPM), growers can break the cycle of spraying—protecting human health and securing their passport to global trade.

Agriplast UV Stabilized insect net installed on nethouse sidewall to prevent pest entry

How Insect Nets Cut Pesticide Use & Boost Food Safety

Relying solely on chemical pesticides is becoming increasingly unsustainable for commercial agriculture. Beyond the high recurring cost of chemicals, farmers face the risk of pest resistance, where insects eventually become immune to sprays.

More critically, high pesticide usage is the number one reason for the rejection of Indian produce in the EU and US markets. To access premium rates from supermarkets and exporters, farmers must demonstrate that their produce is safe. Physical barriers like insect nets are a simple and effective way to break the cycle of constant spraying.

A 2023 Research by Jayashankar Telangana State Agricultural University research focused on Indian agricultural exports shows that exceeding importing-country Maximum Residue Limits (MRLs) and the use of pesticide molecules banned or restricted in the EU and US are among the primary reasons for rejection of Indian consignments.

How Does Insect Net Work?

Unlike chemical pesticides, insect nets work on the principle of exclusion. By covering a polyhouse, net houses or even open field structure with a fine mesh, you physically deny pests access to the plants.

To understand how insect nets work better, we need to dive deeper into the kinds of insect nets and the different sizes.

- Understanding Insect Net By Size

- Understanding Insect Net By Properties

Selecting the correct insect net is not just about mesh size. Performance depends on a combination of mesh configuration, yarn diameter, light diffusion, and UV stability. Based on Agriplast technical data and field observations, the following parameters are critical when choosing an insect net for agriculture.

Choosing By Mesh Size

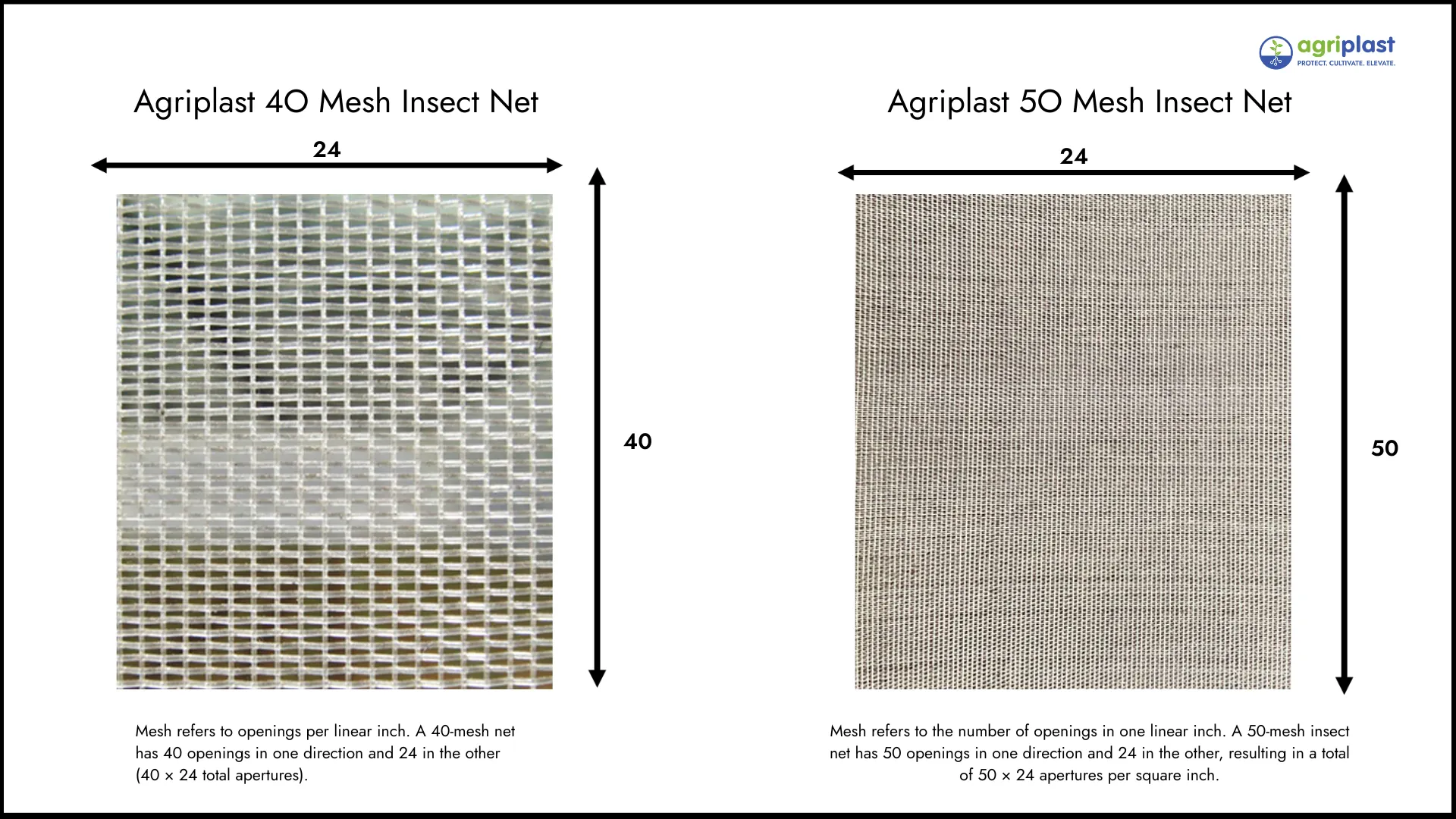

What Does “Mesh” Mean?

Mesh refers to the **number of openings per linear inch.

For example:

- 40-mesh insect net has 40 openings in one direction and 24 in the other, resulting in 40 × 24 total apertures per square inch.

- 50-mesh insect net has 50 openings in one direction and 24 openings in the other, resulting in 50 × 24 total apertures per square inch.

Because a 50-mesh insect net has a higher number of apertures per square inch, the individual hole size is smaller compared to a 40-mesh net. This makes it more effective at blocking smaller insects such as thrips and whiteflies, which are primary vectors of viral diseases in protected cultivation crops.

Smaller mesh sizes mean smaller openings, which improve insect exclusion but can slightly reduce airflow.

How To Choose The Right Mesh Size?

The right mesh size depends on pest pressure, crop sensitivity, ventilation requirements, and disease risk.

- 40 mesh is often sufficient where pest pressure is moderate and airflow is a priority.

- 50 mesh becomes critical in regions with high populations of thrips and whiteflies, especially in virus-sensitive crops grown under protected cultivation.

To make the right choice, farmers must look beyond mesh size alone and consider fiber diameter, UV stabilization, airflow management, and optical properties—factors we will break down further when comparing regular insect nets with advanced solutions like Optinet.

40 mesh vs 50 mesh insect net comparison showing aperture density

Choosing By Thickness

While mesh size determines which insects are blocked, the thickness of an insect net—measured in GSM (grams per square meter)—determines its durability and real-world performance. In Indian conditions, nets face intense solar radiation, wind stress, dust, and frequent handling, making correct GSM selection critical for mechanical strength, UV resistance, and long-term cost efficiency.

How GSM Affects Performance

- Higher GSM (thicker fibres): Improves tensile strength, tear resistance, UV stability, and lifespan under harsh exposure.

- Lower GSM (lighter fabric): Allows slightly better airflow and lower upfront cost but degrades faster in open or semi-protected environments.

A common mistake is selecting the right mesh size while under-specifying GSM, leading to early tearing, fibre brittleness, and frequent replacement.

Typical GSM Ranges in Agriculture

- 40 Mesh: 105–120 GSM: Balanced airflow and durability; suitable for open-field and protected cultivation.

- 50 Mesh: 130–135 GSM: Higher GSM compensates for smaller apertures; preferred in high pest and virus-pressure areas.

(As mesh size increases, fibre diameter must increase to maintain strength—hence higher GSM in 50-mesh nets.)

Why Fibre Diameter Still Matters

Two nets with identical GSM can perform differently depending on fibre diameter and material quality. Thicker fibres deliver greater mechanical strength, improved UV stabilization, and reduced breakage during installation and cleaning. Agriplast testing shows that even a small increase in fibre diameter can result in over 40% higher fibre cross-sectional area, significantly extending service life.

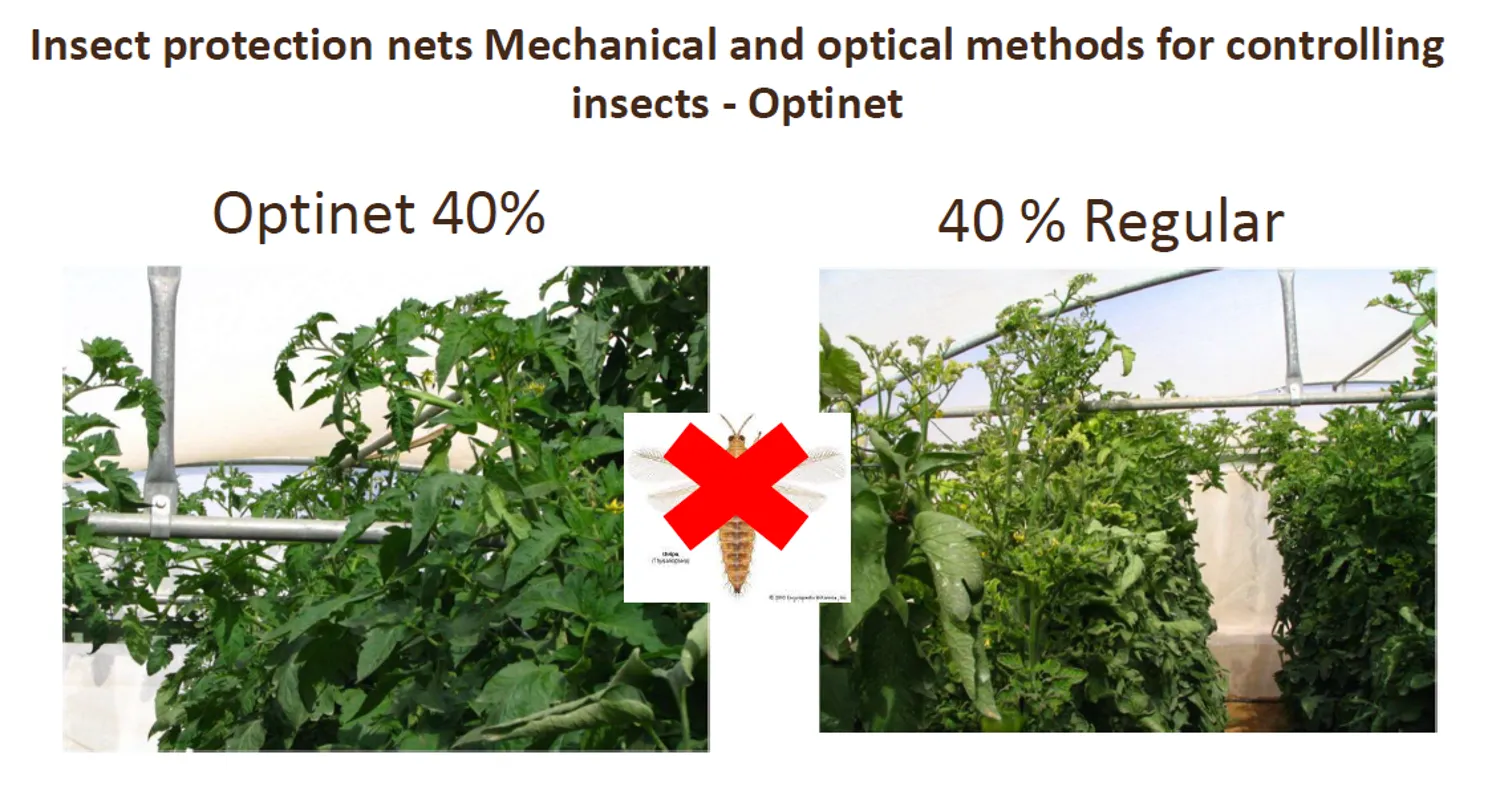

Understanding the Science Behind OptiNet

Conventional insect nets rely only on mechanical exclusion, blocking pests based on mesh size. While effective to a degree, this approach alone struggles against highly mobile, light-sensitive insects such as thrips, whiteflies, and leafminers.

OptiNet, developed by Ginegar, adds a second layer of protection—optical control.

How Insects Navigate Using Light

Many agricultural pests depend heavily on ultraviolet (UV) light for navigation, host identification, and landing. Traditional insect nets allow UV radiation to pass through, enabling insects to visually detect crops even when physical entry is restricted.

What Makes OptiNet Different

OptiNet integrates proprietary, non-toxic optical additives that block and reflect UV wavelengths critical to insect orientation. This creates an optical disorientation effect, where insects experience:

- UV reflection and scattering

- Visual confusion (“dazzling”)

- Loss of orientation before landing

As a result, insects are repelled before sustained contact, reducing pressure on the net and limiting penetration attempts.

Behavioral Control, Not Just Exclusion

Public Ginegar literature confirms that OptiNet works by UV blocking and reflection, targeting insect behavior rather than relying solely on smaller apertures. This optical barrier complements physical mesh protection, especially where pest pressure is high.

Proven Impact in the Field

Ginegar reports up to 5× lower pest penetration with OptiNet compared to standard 50-mesh nets—particularly against thrips, whiteflies, and leafminers, which are key viral disease vectors.

Why It Matters

When combined with proper mesh size, GSM, GAP/IPM protocols, and airtight installation, OptiNet enables farmers to shift from reactive pesticide spraying to preventive pest exclusion, improving:

- Food safety

- Worker health

- Environmental sustainability

- Access to residue-sensitive markets

How to Choose the Right Insect Net: 40 Mesh vs 50 Mesh vs OptiNet

| Selection Criteria | 40 Mesh Insect Net | 50 Mesh Insect Net | OptiNet (40 Mesh) |

|---|---|---|---|

| Primary Purpose | Basic physical pest barrier | Advanced physical pest barrier | Physical + optical exclusion |

| Mesh Openings | 40 × 24 apertures/sq. in | 50 × 24 apertures/sq. in | 40 × 24 apertures/sq. in |

| Insects Blocked | Aphids, larger insects | Thrips, whiteflies, aphids | Thrips, whiteflies, leafminers |

| Virus Vector Control | Limited | High | Very high |

| Airflow | Higher airflow | Slightly reduced | Optimised airflow |

| Recommended GSM | 105–120 GSM | 130–135 GSM | ~130 GSM |

| Pest Penetration Risk | Moderate | Low | Very low (up to 5x reduction) |

| Best Suited For | Low–moderate pest pressure | High pest & virus pressure | High-value, residue-sensitive |

Economic Benefits for Farmers

- Reduced Chemical Costs: Farmers report a 40% to 80% reduction in pesticide purchase costs.

- Higher Market Value: Produce grown under nets is cleaner, has fewer blemishes, and qualifies for "Residue-Free" pricing.

- Disease Prevention: By blocking vectors like whiteflies, you prevent devastating viral outbreaks that can wipe out an entire season's yield.

Improving Food Safety for Premium Market Access

Food safety is the new currency in agriculture. Supermarkets and export houses require rigorous testing for chemical residues.

When you install high-quality insect nets, you drastically lower the "chemical load" on the plant. This ensures that when your produce is tested, it falls well below the Maximum Residue Limit (MRL). This compliance is your gateway to exporting to strict markets like Europe or selling to premium Indian retail chains.

What is the lifespan of an agricultural insect net?

High-quality, UV-stabilized insect nets, such as those provided by Agriplast, typically last 3 to 5 years depending on solar radiation exposure and maintenance. Non-stabilized nets may degrade within months under the harsh Indian sun, becoming brittle and tearing easily. Always check for a UV warranty when purchasing agricultural textiles.

How to Install Insect Nets / OptiNet: Best Practices

Correct installation is critical to insect-net performance. Even small gaps or loose edges can become entry points for pests. Whether used in greenhouses, net houses, or open fields, insect nets must be installed taut, sealed, and gap-free to form a continuous physical barrier.

Greenhouse Installation

- Placement: Insect nets are typically installed on sidewalls, vents, and air inlets.

- Fixing System: A spring-and-channel (zig-zag spring) system is widely used.

- Gap Sealing: All edges must be overlapped and sealed against the frame.

Net Houses & Walk-In Structures

- Full Sidewall Coverage: Nets are usually installed along the full height of sidewalls.

- Structural Support: Wide openings should be supported with metal or PVC frames.

- Secure Corners: Corners and joints must be tightly fastened using clips, ropes, or springs.

Open Field Installation

- Support Systems: Mounted on hoops or vertical poles to keep elevated above crop canopy.

- Ground Sealing: Edges may be weighted or buried to stop insects from crawling underneath.

- Early Installation: Nets should be installed early in the crop cycle—ideally at planting.

Conclusion

Insect nets are not just a protective cover; they are an investment in the quality and safety of your food. By reducing pesticide use, you not only save money but also open doors to lucrative export markets that demand residue-free produce.

Ready to secure your crops? Browse our range of Agriplast Insect Nets or contact us today for an expert consultation.

Frequently Asked Questions (FAQs)

Blog written and Posted by

Abhinav Roy

Abhinav Roy is an agribusiness professional, agricultural communicator, and host of AgriTalk by Abhinav Roy. He works closely with farmers, agripreneurs, across India to simplify complex agricultural technologies into practical, field-ready insights. With hands-on exposure to protected cultivation, crop protection systems, and farm economics, Abhinav focuses on bridging the gap between science, sustainability, and scalable farming solutions.You can write your view/comments here

Recent Posts

Need Expert Assistance?

Get personalized recommendations for your greenhouse, polyhouse, or irrigation needs.

-

Bengaluru (Corporate Office)

- 918141446666

- support@agriplast.co.in

WeWork Roshni Tech Hub - 1st floor, PFS Club House, Marathahalli Main Rd, R.J.Gardens, Lakshminarayana Pura, EPIP Zone, Chinnapanna Halli, Bengaluru, Karnataka 560037